CUSTOMER

Designer and supplier of ruggedized computer and communications systems

APPLICATION

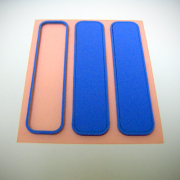

Gasket seal used in rugged PDA for military

MATERIAL

Neoprene (40 durometer) with Tesa 4965 on one side

KINGZOM ADVANTAGE

Fast prototypes, consistently met tight specifications, quick lead time for design phase and production.

CHALLENGE

The customer needed Kingzom to produce a sealing gasket for their rugged PDA for military use in war zones. The gasket had to meet Mil-810E specifications, which includes 24 testing categories that range from low pressure (altitude) to fungus exposure to explosive atmosphere.

The gasket had to meet a tight tolerance of .005″

The wall thickness could be no larger than .080″ In addition, the customer also needed the gasket to be prototyped and produced quickly.

SOLUTION

Kingzom developed the gasket to meet the military specifications and quickly provided prototypes to the customer.Kingzom proved that it could meet the tolerances and wall thickness on a consistent basis during production.

CUSTOMER BENEFITS

Customer avoided tooling costs for the custom-molded O-ring.

Customer could test the materials through all stages of design to ensure tolerances were met regularly.

Due to Kingzom’s flexible design capabilities, the customer had a quicker lead time for design phase and production than it would have had with any other converters.