Injection Molding Label Iml In Mould Labeling Systems For Pp Resin Containers

Short Description:

Product Detail

FAQ

Product Tags

Product Description

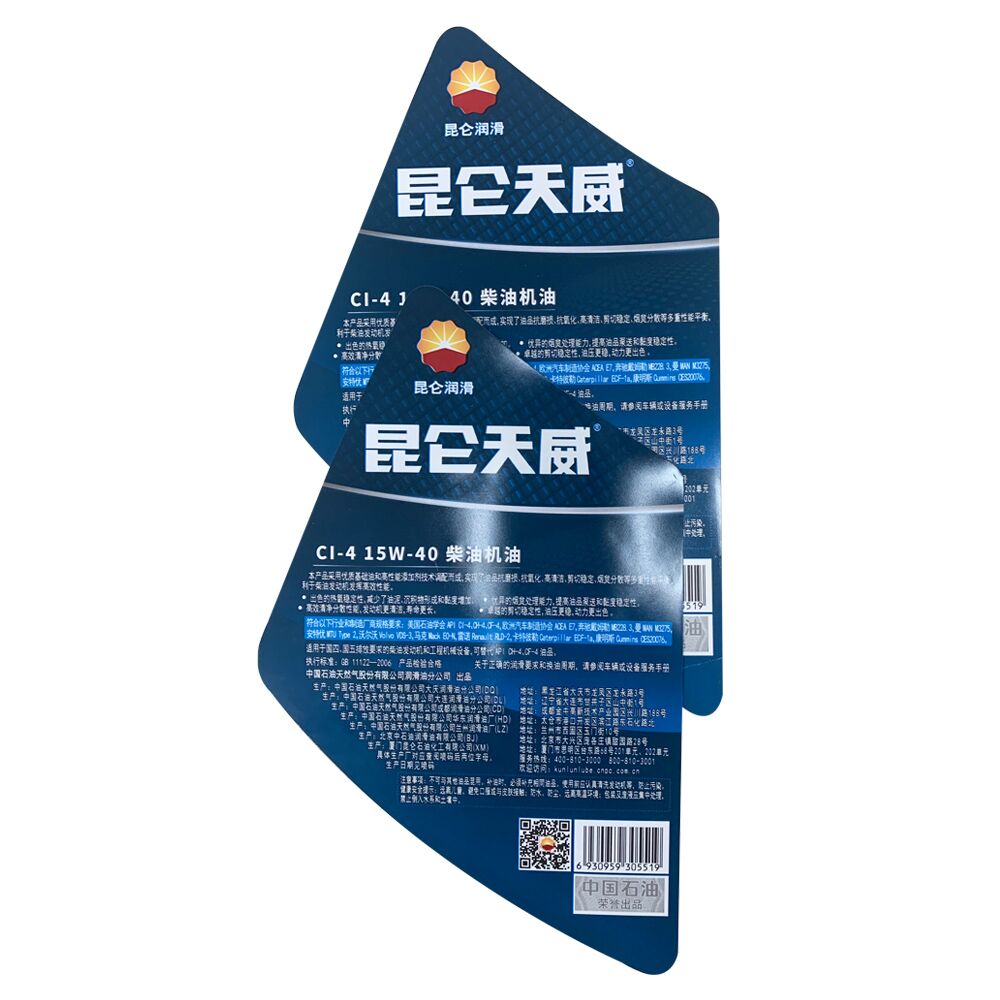

In-mold labeling refer to pre-printed paper, synthetic or thin-coated labels with a special hot-melt adhesive on the back, which is placed inside the model before plastic blowing, injection molding or thermoforming to create a plastic bottle or basin. The label and the container form a whole, the label and the bottle are basically on the same plane. And the edge of the label is invisible, as if the graphic is printed on the surface of the bottle. The use of in-mold labels eliminates the need for labeling machines. Therefore, in-mold labeling is a new technology with great potential.

Product Features

- Excellent printing performance, suitable for a variety of printing methods.

- Fast ink-drying and bright colors.

- Orange-peel effect and smooth lines after finished.

- Good corona treatment ability, no breach.

- Low static, easy for die-cutting.

- No mutual adsorption between labels to ensuring smooth labeling of manipulator.

- Low weight and high yield.

- Good temperature resistance, the injection port will not be black or broken.

- Suitable for both of the cup body and the cup cover.

- Suitable for labeling of PP resin containers.

Datasheet

| Item | Value | |

| Model No. | ZUB-J 70 | |

| Out Performance | One side glossy, one side matt | |

| Thickness (μm) | 70 | |

| Density (g/cm³) | 0.6 | |

| Weight (g/m²) | 42.0 | |

| Gloss (%) | Glossy Side | 75 |

| Matt Side | 13 | |

| Whiteness (%) | 77 | |

| Opacity (%) | 85 | |

| Surface Resistance (Ω) | Glossy Side | 1*1011 |

| Matt Side | 1*1012 | |

| Tensile Strength (Mpa) | MD | 49 |

| TD | 80 | |

Application

Cosmetics industry, pharmaceutical industry, cleaning supplies, oil bottle stickers, etc.

FAQ Content