UV release tape double sided easy to pick up for wafer back grinding (BG TAPE)/semiconductor polishing

Short Description:

Product Detail

FAQ

Product Tags

Kingzom UV series tape including wafer cutting tape and glass cutting tape,could be produced upon your processing and requirements in our dust-free workshop. For example, the film and adhesive can be customized. Our UV cutting-tape materials outshines those expensive but single imported-ones.

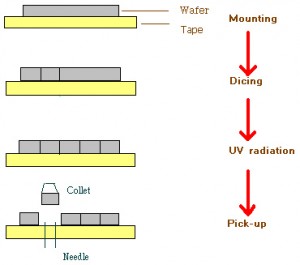

UV release tape double sided is designed for processing of wafer grinding, cutting, fine electronic components, also suitable for all kinds of processing or cutting of small parts. Its high adhesive effect enables it to stick to the wafer, and it can even settle the small parts surely, thus ensure it works exactly during the grinding and cutting process. You needn’t to worry after processing. The adhesive force can be reduced instantly just by exposure it to moderate ultraviolet radiation. Then the wafer can be picked up easily without leaving residue or contamination on the surface after the tape removed. The IC keeps intact in the irradiation.

Product Information:

Name:UV release Tape,wafer grinding/polishing/cutting tape

Brand:Kingzom

Color:Transparent/Customizable

Specification:0.11*300mm*100m (the thickness and width can be customized)

Product Features:

1.Offer great adhesion during cutting; the adhesive strength reduces after UV irradiation, making it easy to be peeled off without residue but settle the wafers surely.

2.Respond quickly to UV irradiation, thus improve work efficiency.

3.Keep the wafer intact and reduce chips during the processing(no particles lost).

4.Settle the wafers firmly and protect them against moving or falling off; stop water permeating into the wafer and tape.

5.Moderate flexibility.

6.Can supply UV tapes and customized size according to individualized requirements.

7.Excellent cutting and loading performance.

8.Suitable for back side of the wafer which is low temperature.

Application:

EMC or ceramic-substrate LED lamp beads, QFN, PCB, packaged semiconductor chip Package, PLC components, fiber optic components, glass filters and so on.

Attention:

1.Please clean the surface of the adhered before use and make sure that there is no oil contamination,dust,water,etc.

2.It should be wrapped in shading bag and placed in cooling environment. Avoid putting it in the sun otherwise the adhesion would be reduced.

3.The temperature should be 10℃to 30℃,otherwise it may cause splicing failure.

4.Please avoid touching the tape surface by hand directly when use it.

5.Please change new tapes;don’t reuse it if put at the wrong position initially.

With qualified R & D team and advanced technology, Kingzom becomes a leader in the industry and has the ability to develop new/customized products for you.

FAQ Content